Are my concrete forms holding the concrete?

Konrad___far_north

13 years ago

Featured Answer

Sort by:Oldest

Comments (39)

manhattan42

13 years agoKonrad___far_north

13 years agoRelated Professionals

Fort Lewis Architects & Building Designers · Nanticoke Architects & Building Designers · Broadlands Home Builders · Miami Home Builders · Puyallup Home Builders · West Jordan Home Builders · Yorkville Home Builders · Hainesport General Contractors · Galena Park General Contractors · Arizona City General Contractors · Chillicothe General Contractors · Corsicana General Contractors · Hamilton Square General Contractors · Kemp Mill General Contractors · Sauk Village General Contractorsmanhattan42

13 years agosierraeast

13 years agoKonrad___far_north

13 years agosierraeast

13 years agogalore2112

13 years agosierraeast

13 years agosue36

13 years agosierraeast

13 years agoworthy

13 years agosierraeast

13 years agoKonrad___far_north

13 years agomacv

13 years agosierraeast

13 years agoKonrad___far_north

13 years agosierraeast

13 years agoKonrad___far_north

13 years agosierraeast

13 years agoKonrad___far_north

13 years agosierraeast

13 years agomariend

13 years agoKonrad___far_north

13 years agomacv

13 years agoKonrad___far_north

13 years agoKonrad___far_north

13 years agoKonrad___far_north

13 years agoMark Bischak, Architect

last yearMark Bischak, Architect

last yearworthy

last yearlast modified: last year3onthetree

last year3onthetree

last yearL Clark (zone 4 WY)

last yearRyan Skiffington

8 months agoKonrad..just outside of Edmonton Alberta

8 months ago

Related Stories

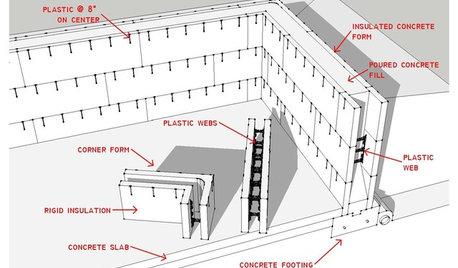

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

DESIGN DICTIONARYBoard-Formed Concrete

Pouring concrete the old-school way leaves attractive wood-grain textural imprints

Full Story

CONCRETE10 Solid Ways to Feature Concrete in Your Home

See how this versatile material holds up as countertops, fireplace surrounds, floors and more

Full Story

FIREPLACESConcrete Panels Create a Stylish Modern Fireplace

A dozen distressed custom panels form a cohesive look without the mass that can sometimes lead to cracking

Full Story

DESIGN DICTIONARYPoured Concrete

No longer just for foundations, poured concrete is taking center stage in homes and gardens

Full Story

MODERN ARCHITECTUREHouzz Tour: A Concrete Box Home With Japanese Style

A love of Japan’s minimalistic style and the use of concrete make for a mystical experience in this Houston home

Full Story

CONCRETEConcrete Block Style

Industrial flair: See why concrete brick isn't just for retaining walls anymore

Full Story

MATERIALS10 Cool Things to Do With Concrete in Your House

Humble concrete is being reinvented in everything from bathroom fixtures to lampshades

Full Story

DESIGN DICTIONARYPrecast Concrete

Made offsite, precast concrete increases quality and decreases installation time

Full Story0

PRODUCT PICKSGuest Picks: Concrete Ideas for Patios and Decks

Look to lightweight fiber cement for functional outdoor furniture and accessories that are heavy on style

Full StoryMore Discussions

res2architect