Cement and perlite vs. cement and sand

Fleur

16 years ago

Featured Answer

Comments (23)

valolson1

16 years agolast modified: 9 years agoRelated Professionals

Belmont Landscape Architects & Landscape Designers · Oconomowoc Landscape Architects & Landscape Designers · Severn Landscape Architects & Landscape Designers · McKinney Landscape Contractors · Cicero Landscape Contractors · Cordele Landscape Contractors · Crystal Landscape Contractors · Dickinson Landscape Contractors · Hicksville Landscape Contractors · Lady Lake Landscape Contractors · Lynwood Landscape Contractors · Manhattan Landscape Contractors · Nashua Landscape Contractors · Pueblo West Landscape Contractors · Wailuku Landscape Contractorsbillie_ann

16 years agolast modified: 9 years agotehuti

16 years agolast modified: 9 years agoFleur

16 years agolast modified: 9 years agoelephantear

16 years agolast modified: 9 years agotehuti

16 years agolast modified: 9 years agoelephantear

16 years agolast modified: 9 years agovalolson1

16 years agolast modified: 9 years agoFleur

16 years agolast modified: 9 years agofredw10

16 years agolast modified: 9 years agovalolson1

16 years agolast modified: 9 years agobillie_ann

16 years agolast modified: 9 years agogarden-smitty

16 years agolast modified: 9 years agoFleur

16 years agolast modified: 9 years agoeva1429

16 years agolast modified: 9 years agotamahlee

16 years agolast modified: 9 years agospat72

16 years agolast modified: 9 years agoFleur

15 years agolast modified: 9 years agowannadanc

15 years agolast modified: 9 years agoHU-845427009

4 years agodarcoob

4 years agoHU-854304790

3 years ago

Related Stories

REMODELING GUIDESFiber Cement Siding Takes a Front Seat

Not just a wood or vinyl substitute, fiber cement is a stellar siding choice in its own right for modern home exteriors

Full Story

REMODELING GUIDESSeal the Deal With Fiber Cement Siding

Chameleon-like, durable and low maintenance, fiber cement gives home exteriors of all shapes and styles a winning edge

Full Story

TILEEpoxy vs. Cement Grout — What's the Difference?

Grout is grout, right? Nope. Cement and epoxy versions have different appearances, durability and rules of installation

Full Story

TILESo Many Reasons to Love Cement Tiles

You’ll notice their beautiful patterns right away, but cement tiles have less obvious advantages too

Full Story

TILEWorld of Design: How Modern Geometric Designs Are Reinventing Cement

Intricate and eye-catching, the patterns of today’s cement tiles mark a break with their past while preserving an age-old technique

Full Story

MATERIALSFloor Material: Handmade Cement Tile

Stylish, durable and customizable, this material can bring a bold pattern to your home

Full Story

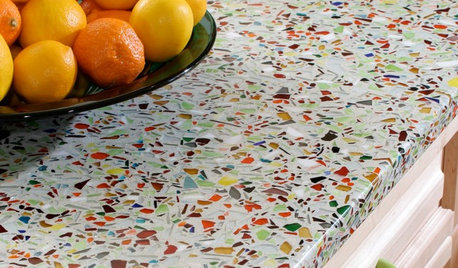

KITCHEN DESIGNKitchen Counters: Sturdy, Striking Recycled Glass With Cement

Ecofriendly and full of character, this heat- and scratch-resistant material is a great fit for custom kitchen counters

Full Story

REMODELING GUIDESWisdom to Help Your Relationship Survive a Remodel

Spend less time patching up partnerships and more time spackling and sanding with this insight from a Houzz remodeling survey

Full Story

REMODELING GUIDESContractor Tips: How to Install Tile

Before you pick up a single tile, pull from these tips for expert results

Full Story

GREAT HOME PROJECTSHow to Replaster (or Remodel) Your Pool

Have an old pool? It could be time to update the plaster, landscaping and more for a pool that works swimmingly with your current style

Full Story

tehuti