Diagnosing my Mothers AC problem?

15 years ago

Related Stories

REMODELING GUIDESThe Hidden Problems in Old Houses

Before snatching up an old home, get to know what you’re in for by understanding the potential horrors that lurk below the surface

Full Story

HOUSEKEEPING10 Problems Your House May Be Trying to Show You

Ignore some of these signs and you may end up with major issues. We tell you which are normal and which are cause for concern

Full Story

MOST POPULAR5 Ways to Hide That Big Air Conditioner in Your Yard

Don’t sweat that boxy A/C unit. Here’s how to place it out of sight and out of mind

Full Story

LIFE6 Ways to Cool Off Without Air Conditioning

These methods can reduce temperatures in the home and save on energy bills

Full Story

DECORATING GUIDESFrom Queasy Colors to Killer Tables: Your Worst Decorating Mistakes

Houzzers spill the beans about buying blunders, painting problems and DIY disasters

Full Story

LIGHTINGHouse Hunting? Look Carefully at the Light

Consider windows, skylights and the sun in any potential home, lest you end up facing down the dark

Full Story

PETSSo You're Thinking About Getting a Dog

Prepare yourself for the realities of training, cost and the impact that lovable pooch might have on your house

Full Story

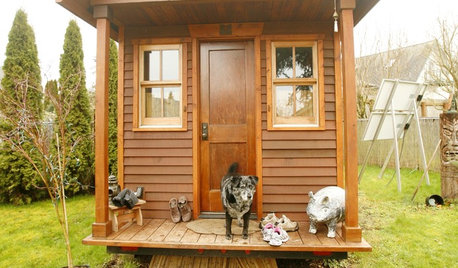

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

KITCHEN DESIGNThe Cure for Houzz Envy: Kitchen Touches Anyone Can Do

Take your kitchen up a notch even if it will never reach top-of-the-line, with these cheap and easy decorating ideas

Full Story

GARDENING AND LANDSCAPING11 Ways to Make Your Sleeping Porch Even Better

Turn off that air conditioner and tune in to the delights of slumbering in the nighttime breeze

Full StoryMore Discussions

garymunson_2009

garymunson_2009

Related Professionals

Lockhart Solar Energy Systems · Maple Grove Solar Energy Systems · Moorpark Solar Energy Systems · Muscatine Solar Energy Systems · Wildomar Solar Energy Systems · Bozeman Home Automation & Home Media · Brookfield Home Automation & Home Media · Brookline Home Automation & Home Media · Plainview Home Automation & Home Media · Saint Petersburg Home Automation & Home Media · San Bruno Home Automation & Home Media · Waterford Home Automation & Home Media · Channelview Fireplaces · Fairfield Fireplaces · Mauldin Fireplacesdearjimmy65Original Author

fluffybunnysui

dearjimmy65Original Author

garymunson_2009

dearjimmy65Original Author

myneonsport

garymunson_2009

dearjimmy65Original Author

garymunson_2009

refrigman1