Mystery Moisture in Slab Ruined Engineered Wood Floor. Now What?

I am stumped and need a little help. Here's the background: I purchased this home 2.5 years ago & remodeled before moving in. It is on a slight grade, so as recommended by my foundation guy, I added drains along the higher side of my house to divert water that would have been going under my house out to the street instead. I also installed 3/8" thick Mohawk engineered wood floors with urethane glue on top of the slab. The contractor said he did a moisture test of the slab 1st and it was fine, but I didn't personally see this happen. He also said no moisture barrier was needed.

Within about 2 months of moving in, I noticed the ends of the planks were peaking in a particular strip in my living room. I blew it off. A few more months went by & I noticed a hump forming in my living room where the glue was failing. Within a year, I had a bump like a pitcher's mound in my living room, and next to it was a 3' diameter area of blistering & bubbling on the wood's surface, and in other areas the wood was turning nearly black.

Here's where I am now: A sewer line at the other, down-hill side of the house was replaced 2 months ago. Now 3 different plumbers have tested and say there is no leak in or above my slab. The wood floors were ripped out last week and I have tested the slab with a moisture meter. I have a definite path of high moisture through the middle of my living room. Moisture readings around the perimeter of the house are acceptable.

Here are my assumptions:

1. I have to find the source of the water and have a consistently lower moisture reading in the problem area before I put in any new wood floors.

2. The source of the water is not my plumbing, nor is it poor drainage around the house because the slab is dry around the exterior walls.

Here are my questions:

1. Where on earth is this water coming from?

2. What type of professional should I contact for help now?

3. Is it possible the moisture was coming from the cracked sewer line in a different - and more downhill - part of the house? If so, how long would it take for the slab to dry out now that the leak has been fixed?

4. How long does the slab need to be dry before I put in new floors?

5. Someone recommended drilling -or jackhammering!- a hole in the slab in the moist area to see what's below it. I know water follows the path of least resistance & so may not be coming from the same spot that's wet. Is this a worthwhile idea?

Thanks a ton for your input.

Comments (149)

exp

4 years agoWe have not and the floors are only getting worse. The 531 didn't do much to help and I really believe that is due to another faulty application. There were still huge chunks missing from the slab that the installer said would be okay to fill with epoxy (i read that they are to be patched using a special compound). We are going to eventually have to remove these floors and just float something or put tile down. Definitely won't be gluing down hardwood or engineered wood floors

Khar Samson

4 years agosorry to hear that. i hope you get to a solution soon. do you recall what was the filler to use under 531? i called titebond they just said it has to e cementations and not polyurethane.

HU-301436582

4 years agoI am in Dunedin Fl, just purchased my first home and we are doing a total remodel. As we start ripping up existing laminate we see mildew on the underlayment, as we remove it we see Regard was applied to the entire concrete floor (a substance applied to backerboards in bathrooms for moisture, as I scrape it up I see mildew under it. There are spots in the concrete that look wet and others that look dry. However, if I lay a paint can down and move it a day later there is a damp spot underneath. We have a wet slab. At first I thought it was bad drainage but it Hasn’t rained in weeks. After lots of professional opinions and $$$ I had a guy that came highly recommended tell me it’s a “natural phenomenon“ where water deep underground (whether it be a mile away or 10 miles away) finds lower ground and air pockets to seep up from-just so happens to be under my house :0(. No leaks, no sounds of running water, no spinning water meter. Its Becoming more of a common thing in FL and we are now at a standstill with $3500 worth of vinyl plank and $1700 of purchased carpet sitting there in the house because we don’t have any solutions. I’m beyond distraught and losing my shirt over paying multiple “professionals“ to give me their opinion but no answers while paying rent and mortgage because We can’t move forward. I spend my free time scowering the Internet looking for answers and people in similar situations. The most definitive suggestion we got was to “grind/rough up” the concrete and then apply Ghostshield vapor tek or purchase a wood floor and use a mastik (due to the pics above) I think that would just be covering the problem and hoping it goes away. I’m desperate for answers and willing to share my story to hopefully get some insight and stop giving my money to “professionals” who make a living giving faulty solutions for others misfortunes. To add insult to injury, it was never disclosed to us prior or we would have never bought the house and dealt with this nightmare. Help!

SJ McCarthy

4 years agoSorry this is happening to you. Several things need to be explained before going into the 'fix'. First of all, concrete is POROUS which means to say water moves through it quite nicely. In fact, once concrete has been poured, the water inside it evaporates by moving up wards. This action creates teeny tiny little tubes that allow MORE moisture to move through it faster. This is called capillary action. In essence your slab (and everyone else's for that matter) has hundreds of thousands (if not millions) of little tunnels that act like little straws...drawing moisture up towards the air (which is naturally drier than a water logged slab).

In theory, this capillary action ends once all the moisture has been removed from the slab (ie. complete cure). In practice this rarely happens. The most common reason for this: the moisture barrier used below the slab had been compromised (holes poked in it by rocks, etc) or improperly installed (very common).

The other issue: old slabs (mid-80's or earlier) do not have vapour barriers underneath them. To be clear, almost NO slabs had moisture barriers (plastic sheeting) underneath them in the 70's. In the 80's moisture barriers became more common but not 100% of slabs had them. In the 90's moisture barriers became widely used in the industry (almost every slab had plastic underneath).

Your home, depending on WHEN it was built, may not have a moisture barrier underneath it. Whether your slab is missing the plastic, the plastic has been compromised or it was improperly installed before the concrete was poured is immaterial.

Now add this to a slab in Florida where the water table is KNOWN to be high (in some places it sits just a foot or two below the surface...hence all those canals that fill with water). Which means the ground is always moist. Always. You don't need rain to have the ground read as 'wet'. And if the ground is wet, your slab is wet. And if your slab is wet that means moisture is ALWAYS moving up through those little straws (capillary action) and evaporating into the air. So long as the slab is left open to the air you won't have a problem but as soon as you put something over it, it starts to show signs of moisture in it (damp spots underneath a can of paint).

One of the few ways to deal with a wet slab is to seal the entire thing. It is expensive, but it works. The slab is shot blasted. Then the 'wet concrete' specialist sprays or rolls on a moisture barrier (usually two layers...each layer given 1-2 days to cure). Then the slab is primed (cause the moisture barrier is usually very slick in a chemical way). Once the primer has dried, the concrete specialist then apply a topping of new concrete. While they are there you get them to make it as smooth and as flat as possible.

Once this has happened, you now have a sealed slab. In my neck of the woods (the most expensive city in N. America...2nd most expensive in the world) this type of work costs $5-$7/sf to do.

The down side of this (sigh...I know...the cost isn't even the down side) is the ENTIRE SLAB must be dealt with all at once or it won't work. Yep. Every single square inch of slab must be sealed or it won't work. That includes under the kitchen, under the tiles in the bathroom, under walls, etc. When dealing with a finished home, it is very difficult.

Moisture mitigation is a weird science that requires you to have a firm understanding of (wait for it...) SCIENCE! Yep. This takes some SERIOUS chemistry geeks (love the science nerds at Mapei...they are AWESOME!) to understand this...let alone fix it.

And one of the things about the building industry is this: many people enter it because they are good with their hands...not with school. I admire anyone who works a trade. People with honesty and integrity and skill always have my appreciation.

But sadly, moisture issues are like voodoo to many in the building industry. Not because they are 'stupid' but because they didn't get a Bachelor of Science in Chemistry. You have to stay in school - and continue for many years in post secondary - to understand hydrodynamics.

I'm sorry you feel like you've been lead down the garden path. It was not intentional...I'm sure the people who spoke to you "didn't know what they didn't know".

At this time, you will want to work with the person who gave you the lesson of water moving up through the earth. So far they are the one's who have proven they have some sort of clue.floorguy

4 years agoYa Joseph, and then all you have to deal with is the white efflorescence of alkaline, peculating to the surface

Joseph Corlett, LLC

4 years agoSo you broom a little now and then. It's the most cost effective, practical and beautiful solution,

Eric L

4 years agowonder if stellar innovations would help with keeping floor dry, maybe if you put spacers in there?

cbgfour

4 years agolast modified: 4 years agoAfter reading this entire post on moisture in a floor, I have come to a conclusion. Once this happens, there is nobody who knows exactly how it happened; there is nobody who knows exactly how to fix it; there is nobody who's opinion or advice you can trust; there are no "experts" out there who can explain how to fix it; spending lots of money to solve it, will not necessarily solve it; you can't sell your house because of this problem. It's your problem, and you somehow have to live with it. I might add, I live in Trinity, FL

cbgfour

4 years agoSpoke to a flooring person today, and he said to put down a floating floor if you have high moisture in a concrete slab. Yes, there will be times when there is moisture under the floor, however, there will be times when there will be less moisture. Moisture in a slab fluctuates, and this will allow that to happen without ruining the floor. What do you think of this idea?

i2086741

4 years agoLook into using Bostik Ultra-Set SingleStep2

https://www.bostik.com/us/Bostik-products/ultra-set-singlestep2-advanced-adhesive

SJ McCarthy

4 years ago@ cbgfour....moisture in a slab is the whole reason why 'floating' floors were invented. Water is the most damaging force on the planet. It can ruin anything and everything. A floating floor utilizes a plastic vapour barrier underneath (or a subfloor system like DriCore) to separate the flooring from the moisture.

Unless you want to spend $5-$7/sf for moisture mitigation on the slab AND THEN pay for flooring and install, then a floating floor is the best solution.HU-497509746

4 years agoFor anyone else who has had this... we have a mysterious area in the middle of the room where the wood was elevated. We can't find the source of the leak without tearing open the slab. The wood was removed and the water damage is localized to that area where the wood is elevated. Any chance you guys had this issue in the middle of the room and not the edges?

floorguy

4 years agoBUCKLING IN WOOD FLOORING:

Buckling is excessive expansion causing the wood flooring to release from the subfloor.

Buckling can be caused by:

Moisture caused by:

· Inadequate or inoperable HVAC system, resulting in elevated humidity(Greenhouse Effect)

· Wet subfloor

· Inadequate moisture control system used under wood flooring

· Excessive jobsite moisture (airborne, subfloor, or flooding)

· Inadequate acclimation

· Grade Conditions

· Pipe leaks

Elevated wood moisture content after installation, is always the main cause of lifted, buckling or tented wood flooring.

Sources of Moisture:

With the introduction of laminated engineered flooring, hardwood floors can be used in virtually every room in the house, even the basement. Water on or near the building site is still a consideration, however. It cannot be ignored.

Installing Below Grade and On Grade:

Moisture comes from a variety of sources – from the earth itself, from surface water(i.e., rain water runoff) as well as from the interiors atmosphere. The use of alternative materials may be necessary when the installation is below grade. Below grade is defined as any part of the slab having less than 4 inches to soil level, from slab height. Additionally, walk-out basements are considered below grade, even if a portion meets above grade requirements.

Potential Sources of Moisture:

Ground Water: Sometimes the level of water in the ground(the water table) is raised above the bottom surface of the foundation due to:

- Heavy prolonged rains

- A spring that appears only during wet seasons

- Water flowing along the impervious layer under the foundation

Any of these may cause water to penetrate the foundation from the sides, or rise through the ground surface into the foundation.

Surface Water: Rain water falling on the ground or from the roof can pass through or under the foundation. In some areas, heavy soils may retain surface drainage and cause water pressure against the foundation(i.e., French drains close to foundations)

Capillary Rise of Ground Moisture: Moisture travels upward in Capillary action – as much as 14 -18 gallons per day have been documented under a 1000 sq.ft. house. Capillary action occurs in nearly all areas where the soil is clay or silt.

Capillary action is the effect of surface tension that causes water to rise upward in a narrow tube, against gravity. In building construction, capillary action can occur between two surfaces placed together, or within porous materials. This relates to the installation of wood flooring, in that moisture can be drawn through the concrete subfloor beneath, from ground moisture.

Minimizing Moisture from Concrete:Traditional construction of homes tends to have regional variation. While many older homes have basements, Southern home building is done on concrete slabs. The slab rests on a prepared base, and is surrounded by footing that extends below the soil line, providing the actual foundation for the house.

The no basement design eliminates many of the moisture problems associated with basements and crawl spaces, but the installation of flooring is not without its own intricacies. Concrete appears to the untrained eye to be a solid, impermeable foundation, yet it’s actually a source in itself for moisture. Concrete expands when it absorbs moisture from humidity, or by exposure to rain and it contracts again when the moisture evaporates.

All concrete surface, regardless of age or grade level, will emit or conduct some degree of moisture, usually in the form of vapor. This is a natural and necessary function of healthy concrete. However, too much vapor emissions without a proper moisture barrier has resulted in numerous flooring failures. Many times the blame for this is placed upon faulty product, improper specification, or faulty workmanship. When the real reason lies with the slab vapor emission conditions.

Because moisture can rise through the concrete by capillary action, moisture barriers and moisture retarders need to be a part of the installation process. Moisture barriers should be used in the formation of the slab, to keep ground moisture vapor to minimum levels, additionally, another moisture barrier should be placed on top of the slab before installation.

There are several moisture barrier systems available, including 2-part epoxy, rubberized elastomeric membranes and other sealing liquids. In all case, installers must verify acceptability of a particular system with flooring manufacturer. If you are not familiar with the system, check with the adhesive manufacturer, the flooring manufacturer and the manufacturer of the moisture barrier, before attempting the installation.

SJ McCarthy

4 years agoFloorguy you ROCK! I was getting pretty tired of writing this stuff out (in pieces) for the last 6 years! Amazing!

Thank you for taking the time. Sadly most people do not take the time to READ what is right there in front of them. Sigh. All those years of education wasted.julieste

4 years agoSo, I've read it all and have a couple questions for those of you who just posted such helpful information in the pat few days. This pertains to a 40 year old 2 story townhouse in FLA that we are remodeling. It's on a concrete slab, and the second floor also has poured concrete floors. We plan to use Karndean Rigid Core LVP for the majority of the place. Lanais and bathrooms will be porcelain tile.

1. Do we need to put a 6 mil vapor barrier down on the 2nd floor under the LVP?2. Do we need to put any sort of moisture barrier under 2nd floor porcelain tile (bath and under-air lanai)?

3. Is a standard 6mil underlayment moisture barrier all we will need on the main floor under the LVP?

4. Will we need to put anything under the porcelain tile in the main floor bath and under-air lanai?Would we be better off having the local floor company we are purchasing our Karndean product from do the LVP install just in the remote case there would be problems down the road with the product?

5. We have a competent and experienced contractor doing our work.

This is costly enough that we want to make sure it is done properly so we won't be acing any problems. Thanks in advance.SJ McCarthy

4 years agoThe 6mil vapour barrier will be required with the LVP over any concrete slab (suspended, at or below grade = doesn't matter).

The isolation membrane for the tiles is a requirement. That is part and parcel to laying tile...even on concrete slab.

And finally, the SUBFLOOR preparation for concrete can be $2-$4/sf. That is where the money is going to go. Without that prep you are almost guaranteed an unsatisfactory install.julieste

4 years agoThank you so much SJ!

Is isolation membrane the stuff that is painted on to the floor?

When you say $2 to $4 per sq. ft for subfloor prep, are you referring to leveling and grinding or the membrane or all of the above or what?SJ McCarthy

4 years agolast modified: 4 years agoSubfloor prep includes everything that is required to get the concrete ready to accept the first product...such as the isolation membrane. That's the grinding, patching, flattening. Self-leveling compound (SLC) is part of it the $2-$4/sf cost. Most of it is labour.

The Ditra or Schluter membrane, cement backer board (if used/needed), thinset, tile, grout, leveling/spacing system, etc is extra.

The state of the existing concrete will dictate the costs of the preparation. A nice slab will be $1.50 - $2/sf. A moderate slab is $3. A really bad slab can be as much as $5/sf...but that is rare.

Vermont Renovation and Restoration

3 years agoWe're working through a similar issue. You may have a spring under the middle of your home that is compromising the concrete. The concrete is like a sponge, it soaks it up (and you don't have a vapor barrier) and then it evaporates into your home. Are you seeing signs of mold on your furniture? There is a seal/epoxy that you can put down on the floor, everything has to be moved out, the floor pulled up, the epoxy put down and then stuff can be replaced. It's a big project but it should solve the problem.

SJ McCarthy

3 years agoA house built in 1960 would be 'as is; where is' which would mean home insurance probably won't touch it.

Capping an old slab (like moving from carpet which breathes to hardwood which doesn't) is an issue. Sadly, no one knows what they don't know. A handy man or flooring 'guy' won't know this. In fact they may only see it 2-3 times in their carriers.

A building chemist (who works for the BIG ADHESIVE companies) will know this. A 'slab guy' may or may not know this. A commercial installer who has 'capped' unsealed commercial slabs will have an understanding of this...but may not know when or where to apply the knowledge in a residential setting.

In essence, an old slab with carpet on it is not always a candidate for 90-100% rigid flooring that 'caps' the concrete. The moisture creeping into areas that have NEVER had an issue is too great a risk.s K

3 years ago@SJMccarthy does that mean that if the engineered wood is removed and then carpet is put the problem will not happen? What about removing the engineered wood and putting tile? I do feel that reinstalling wood can buckle again unless the concrete is treated properly And dried before installing wood again .

SJ McCarthy

3 years agoAsk yourself: what 'breathes' or allows moisture to move through it without interference? Tile? Nope. Tile acts as a 'cap'. Glue-down hardwood? Nope. Acts like a cap. Carpet? Yes...it is a weave. It allows moisture (and air) to move through it. So long as you use a pad that is NOT 100% moisture barrier you are safe.

To get rigid flooring over 90% of an old slab like this, you need to remove all flooring, shot blast it, lay down moisture barrier over 100% of the slab. Then you pour a microtopping of new concrete over top and THEN you allow it to dry.

Once the ENTIRE SLAB is properly sealed, you can then think of putting down rigid flooring like tile or hardwood. Until then, carpet is your friend.kaiegirl123

3 years agoHi everyone, First, THANK YOU to @SJ McCarthy , @floorguy, @G & S Floor Service, and all the other experts for your participation on the Houzz site - we so appreciate your insight/advice. We are in the process of deciding best flooring option for our 1970s single story, concrete slab, home on a canal in FL…(see where I'm goin' with this? ;) and hoping you all can help….

By way of background, we discovered our moisture issue when I lifted a stack of board games off a carpeted floor and discovered mold on the underside of the game box…this prompted checked of underside of a cardboard box sitting directly on the slab in another room and found mold on underside of that box as well. In this room, you could also see the concrete appeared dry everywhere, except beneath the box, where it looked dark and damp…moved the box, and a day later, concrete looked dry. Based on prior posts, I am assuming that since the house is from 70’s there is no moisture barrier beneath slab so the moisture moved through concrete slab, "escaping" thru slab and carpet - which was fine until we rested something on top in which case that moisture was trapped by the cardboard boxes and they developed mold. At that time, we yanked up carpeting, painted floors in those 2 rooms with Dry-Lock, and re-carpeted. That was over a year ago and so far, so good but is it likely that the Dry-Lock will eventually fail?

In terms of other rooms, we have tile in 3 bathrooms and all is well.

We are now in process of replacing the flooring in the 2 carpeted rooms along with the kitchen and 3 other rooms (essentially re-flooring everything except the 3 tiled bathrooms).

All other rooms currently have an old plank style, floating floor (planks appear to be made of hard plastic on bottom with something like a pressed cardboard in the middle, then the wood "picture" on top). In any case, we've pulled some up and there is a lime colored, almost foam-feeling underlayment beneath. This plank flooring is old and ugly but on the plus side, the underlayment did indeed seem to throughly prevent moisture from reaching the floating floor because the top of underlayment felt completely dry while the underside traps enough moisture beneath it that when lifted it’s wet and beads off. Once the underlayment is removed, concrete appears dry after a few days - which makes sense since once the barrier is gone the moisture can just “move thru” the slab and evaporate, yes?

OK, soooo….big question for us now is what type of flooring can work well for us and how best to prep?

Tile?One sales rep recommended tile as best way to go. While we know this will last, this is our least favorite option due to labor, installation mess, wear n tear on our bodies walking on this long term, & difficulty removing if ever want to change. That said, we would consider a wood look tile if it truly is the best option.

Floating Floor?@sjmccarthy said "moisture in a slab is the whole reason why 'floating' floors were invented" .... As long as the appropriate moisture barrier is installed beneath them, can we safely install both LVP and even Wood Laminate floating floors with the moisture in our slab?

LVP?We’d been leaning towards LVP because it’s more truly waterproof but worry about:

- what we’ll be breathing in long term (I believe Phthalates and Formaldehyde are no longer used and there are Low VOC options but still worry).

- If we go this route - we love an option from Mohawk Stonetech but it only has a 12 ml wear layer and while there are just 2 adults in house I do wonder how it would hold up. Not opposed to other brands CoreTech, Shaw, etc just that in terms of appearance, that Mohawk Stonetech is exactly what we were looking for.

- Lastly, while we have newer windows I’ve read sunlight can both fade LVP and cause it to expand, thus popping it up….Can windows be treated effectively enough to prevent this? (Our big windows/sliders face East and get lots of light until late afternoon…..)

Wood laminate?

- We understand there are some great options - Revwood & QuickStep NatureTEK, for example. @sjmccarthy , you mentioned AquaGuard in the past but I’ve read they are only water “resistant”, and also saw some mixed reviews so wondering if you would still recommend this product.

- Most of all though, our overall concern with wood laminate is - is it truly a viable option with our moisture issue? Aside from underlayments, a sales rep said his co applies something like a RedGuard (cant remember name) then Revwood on top without any issues. I know Revwood is waterproof on top, but if it gets wet from beneath it’s toast so appreciate 2nd opinion on that….

Mold beneath Underlayment?

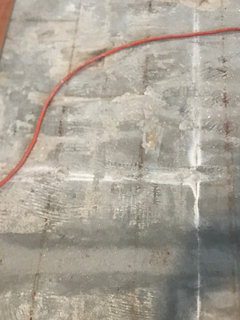

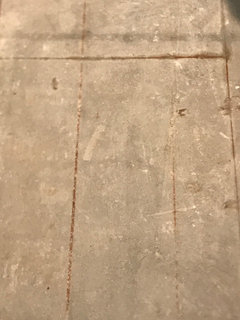

- Lastly, if you are trapping moisture beneath the underlayment, is there a danger of mold developing beneath the underlayment?? I assume there would be anti microbials or something to prevent this but when we lifted the underlayment beneath our existing floor, while there was no obvious signs of any dark mold, there were these rust-colored lines left on the concrete that appeared to follow the outline of the floor planks (pics below) …could this be mold? or maybe rust or dirt??…

DryLock/RedGuard??

- Heavy duty sealing with shot blasting, etc isn't an option for us but we are wondering if there would be a benefit to using DryLock or RedGuard either in lieu of or in addition to an underlayment for added protection….not sure if this is even needed or, worse, could cause a problem…thoughts?

A lot of info/questions I know….so thank you in advance for any thoughts and/or suggestions!

Tcott

3 years agoWhat would cause a new install of water based lament flooring with water proof underlayment installed under, to swell. This flooring was installed over cement floor which had , hardwood, flooring originally,

Floor person said is was fine to install new water proof flooring over hardwood flooring. Now there is a large hump in the floor.

Vermont Renovation and Restoration

3 years agoWe have a house on slab with a moisture content of HI using Wagner Rapid RH testing sensors 4 years after pouring the slab. Snyder Homes who built the condo complex is blaming my mother for the 78% RH levels inside. It molded all the furniture and had to be discarded. We have discovered that URETHANE slurry on the floor will seal all moisture issues, however, it is very expensive and labor intensive. Everything must be moved out, floor removed, counters, vanities, doors, toilets, all out. Concrete slab will be ground down and then a urethane floor installed. Epoxy for a wet slab is NOT a solution (we walked down that path and found out it would fail).

SJ McCarthy

3 years ago@ Tcott Are you saying you installed water proof laminate OVER TOP OF existing hardwood????

Where is the cement? Above, below or at grade? How old is the house???

@ Vermont Reno - Yah...we hear this all the time in the flooring industry. The issue is the 'condo' build. Like commercial builds (warehouses and shops) the condo builders do NOT like to use the heavy duty plastic sheeting under the slabs. Why not? Because these builds are HUGE. Some of them take up entire city blocks. That is a TONNE of plastic (literally...thousands of rolls delivered = tonnes of material). And that plastic has a purchase price and a labour price. So they try to skip it.

I would check your building codes for condos to see if the slabs are required to have moisture barriers underneath the build. If not, then the issue is with code and not with the builder....but it is most likely the builder.

I hope you and your client can find a solution that works...for everyone.Jennifer Johnston

3 years agoAlthough this isn't my original thread, I do appreciate anyone who has taken the time to provide their opinion or insight. Comment HU-301436582 was mine before I made an account.

I am happy to say that we now moved into our home! I know we may not be "out of the woods yet" but we've been here 6 months and so far things are going well. I want to share my experience of "our fix" to this issue in case it could potentially help someone else out there. I am not a professional, nor making personal recommendations, this is just what we did to try to alleviate our specific issue and it seemed to really work for us.

1. We ripped everything off the floor/scrape until it was bare concrete/substrate.2. We rented industrial size dehumidifiers from Home Depot and eventually purchased some of our own and ran them constantly.

3. We put gutters/downspouts up

4. We put two French drains in-one from the middle of the back yard to the street on both sides of the house and another smaller one right along the slab of the house in areas/rooms that seemed to be the worst.

5. We treated it like you would a basement up north, we (our contractor) dug up around the entire perimeter of the house so the slab/footer was exposed and painted a generous amount of rubber cement.

6. We shot-blasted or "roughed up"ever sq inch of the interior substrate then sprayed two coats of VaporTek/Ghost Shield and let dry for 2 days before putting any flooring down. In the week or two from the French drain/rubber cement process we started seeing a difference in the concrete drying up and looking more grey than black/wet.

We put carpet down in the bedrooms, and Lifeproof vinyl floor in the rest/majority of the house and bathrooms. We do still keep the dehumidifiers on auto and so far have had no seepage or bowing of our floors. Update: The dehumidifiers rarely kick on anymore. No more musty smell, no weird condensation issues on windows/walls, no more mold, etc.

I know we felt like we were living a nightmare for a few months so I hope this can maybe help someone and I am happy to answer any questions about our situation.Jo Kay

3 years agoThank you for this. It’s an education. We renovated our house last year and installed underfloor heating and then the builder laid engineered wood floor over concrete slab. All works and looks beautiful apart from one place. We ave a house on a slope so street level and garden level differ by 10 feet. Our kitchen used to open onto a patio and then you had to go down 10 steps to grass. We removed the patio and built a room at grass level that has steps open plan leading up to kitchen area at street level. In that room the engineered wood floor is always warm due to UFH but some of the floorboards are warping and getting wet a year after installation. The issue started in winter and during Covid when were are all at home 24/7. The builder returned and took a few floorboards up and they are damp underneath with beads of moisture on the concrete. As soon as they were taken up the concrete dried quickly as did the floorboard.

Is this a condensation issue? Although this lower level is open plan to the upper level kitchen the problem seems to be happening at the area where least air circulation would be. My daughter put some plastic play houses on the floor and when we tidied them away they were wet underneath and had stained the floor. The builder says that water isn’t coming in from a leak or from a damp problem. But he’s never seen this happen before.

Any advice would be greatly appreciated

SJ McCarthy

3 years agoThe vapour barrier in the concrete could have been pierced of compromised in some way...the builder will be able to tell you what he used, how he used it and how it might have been compromised.

The way water flows is downhill. It can be extremely tricky to get the water proofing right on an addition such as yours. Tying in existing water from the existing structure to an addition that creates an inside wall from an outside space.

You can ask for the architectural blue prints that were submitted to city hall for approval. And then you can compare that to what the builder used for construction.

How much did you pay for this addition? How many square feet did it add to your home?Jo Kay

3 years agoHi- it added 30sq metres. It was about £70k to add it. We are in the UK so we get a lot of rain. The builder has come back to fix the problem but he said that it if was the ufh then the system would lose pressure and not work. He said that it’s a thick membrane and we have a pump under the terrace that pumps groundwater to the mains. We have membrane, concrete, ufh and then more concrete and then the wood. It could be a tear in the membrane. I really hope not 😩

SJ McCarthy

3 years agolast modified: 3 years agoOK...translation for those of us in the Colonies. You've added 300sf (a little closer to 350sf to be honest) for 70,000 English pounds ($126,000 CND).

The membranes REALLY need to sit HIGHER than the ground level so that splashing doesn't hit any side of the home and then cause seepage. The place MOST LIKELY to leak = the connection where one building meets the other. This is why it is so tricky to get this right. The roof is another major issue where old house meets the new.

If you could start another thread with photos of the issues AND the before, during and after completion of the addition we will try the best we can.

Can you explain 'ufh' for us?

Jo Kay

3 years agoThanks so much. i've started a new post called "Damp Concrete in floor" and put it all there. I really appreciate your time. I just think that if i can understand what might be going on i'm in a better position to make sure the builder solves the issue properly. UFH is under floor heating.

Jo Kay

3 years agoSJ McCarthy thank you so much for your help you were spot on. The builder removed a section of the wall where the 2 levels meet and there was water inside the membrane. It was dripping down to the concrete floor from behind the plasterboard and spreading underneath the wood floor. Not much water but enough to have caused problems. Apparently the underfloor pump shouldn’t have let the water get that high so that’s being investigated. The wall will need to be stripped back to find the point where the water came in and repair it.

I’m not sure why there seems to be spots of damp across other parts of the floor. Once they’ve put cameras under there we will find out if the underfloor membrane has failed as well.

Thanks for your help as I wouldn’t have pushed it if it weren’t for your guidance.

SJ McCarthy

3 years agoI can't tell you how happy I am that you were able to find the issue. I'm so glad our (Houzzers are quite generous with their time) few minutes of typing could help you find a way out of your horror show.

I'm so sorry this has happened. It sounds like you did everything right (re: architect, contractor, etc) and yet something still went wrong. I really, really, really hope they find the reason for all of this weeping into the new space.

Keep on it! You are doing a great job.Jo Kay

3 years agoJust a quick update. Turns out that due to a water pipe leak we had last year coupled with a lot of rain, the water moved rubble and soil so that where the two floor levels meet between street level kitchen and ground level extension there was a build up of a large amount of water that couldn’t go anywhere. The build up meant that water couldn’t drain away to the part of the extension that has the pump underground. Eventually the pressure built up and so the safety mechanism in the damp course let water through.

The solution was to cut three sections out of the wall and floor, remove the rubble and soil so that the water drained away - and there was also a lot of limescale there - and then think of a way to stop it happening again. They have put 3 “service points” in the wall by the floor - which are vertical drain pipes that bend so that you can access them within the wall. They will be checked periodically to ensure that water is draining away and that limescale hasn’t built up.

The membrane and damp course have been repaired and rejoined, next they have to rebuild those sections of the wall and fill the floor back in.

So lesson learnt is that if you have a lot of groundwater and you need it to drain away, particular around basements, you need to ensure that those drainage points don’t get blocked.

SJ McCarthy

3 years agoWow! What a journey! Good for you for keeping your cool (ha...I know...there were days you didn't feel you were keeping it together...but you still did it!). You pushed the right buttons and the builders are moving on with a solution...I'm assuming on their dime???

Sara Clark

2 years agoJo Kay, we have a similar moisture problem as most on this thread. i notice you mention an underground pump. we thought about that, but when I talked to someone about doing so, they asked how we would know where to put the pump if the whole area is damp. Didnt recommend it, though I’ve heard of it being done. Is iit under the house or where?

Sara Clark

2 years agoTo all of those who have dealt with this type of foundation moisture issue and have put down tile or carpet after having an engineered wood floor, what is your plan to disclose this issue to potential buyers? im about to be in that boat. i feel like the first thing theyll want to do is take up everything and put down a wood floor. which isn't going to work for them! A realtor once told me that she didnt want to know about issues we’d had with a home (didnt want to be obligated to disclose). any input??

Sara Clark

2 years agoSJ Mccarthy: i notice that you talk about remediatiin of the entire slab, which would involve removal of cabinetry, etc. how is this done with walls, etc in place? we currently live in the house. we do have an expensive coating that was put in one room of the house where the engineered wood floor failed. we put slate over the Ditra type membrane. now the adjacent rooms with more wood floor are failing and getting subterrainean termites. if we took that floor up could we put the membrane under that portion or do we need to take up the slate and have it installed at one time? Seems like a terrible thing to deal with!

SJ McCarthy

2 years agoThe slab will tell you how this works. The termites are your WORST problem. Water can be dealt with pretty quickly. The TERMITES can take down a house in 10 years or less. That's where you need to start.

For termites to get into wood flooring over concrete, there must be a WAY for them to get in. That normally means there is some WOOD that is IMBEDDED in the concrete. Or there is wood that is TOUCHING the ground and then the same piece of wood continues INTO THE AIR and INTO THE HOUSE.

Subterranean termites need WOOD that is touching or imbedded IN THE EARTH. That's their 'in'. You must remediate the termites (and get the wood out of the ground to stop the beggars from climbing into your wood floors).

Once the animal-destruction-intrusion is remediated you will then go ahead and deal with the moisture. Your animal remediation will most likely require a large amount of demolition. At that point you will probably have a clean slate - throughout the house - to update everything.

Check to see if your homeowner's insurance covers termite damage.Jo Kay

2 years agoRe the pump Sarah : the pipes are under the house directly under the new room we built. the Pump is under the patio with man hole access to it. The pump works to extract any water under the house. However we live in a city where the houses aren’t big. The pump extracts the water and pipes it out to the drain

Jo Kay

2 years agoAlso update for my learned friend SJ Mcarthey - the water problem is completely solved now. The floor dried out and sank back to normal. And the builder didn’t charge us for correcting the issue.

HU-966881724

2 years agoWas the slab cut to replace sewer line ? they might of removed the moister barrier and not replaced it. they might of put sand around sewer line and not gravel so moister can drain. i would cut hole in slab where moister is coming through and inspect it. thats the only way to know.

kupa2203

2 years agolast modified: 2 years agoI am so glad I found this post. We've been tearing our hair out trying to figure out what was going on with our floors!

We have moisture damage in random locations of our living room and master bedroom floors. The house was built in 1995. For whatever reason we have moisture in our slab, but only towards the back part of the house. It could be a torn vapor barrier under the slab. We've had two plumbers verify there are no leaks in the pressurized lines or the sewage pipes.

A flooring inspector told me on the phone that we were just throwing good money by going with wood and suggested tile. We were planning on replacing with tile but the flooring guy (not the same one that originally put in the floors) told us that it is okay to use wood if installed correctly.

He has suggested using titebond 531 + epoxy floor moisture barrier.

The rest of the 1st floor is capped (tile or wood). Can we try wood floors again in the rooms with the damage or should we put tile or carpet? I appreciate any help. Thanks!HU-503992792

6 months agoWe had our whole house re floored in LVP In June 2021. Within a few months a portion of the kitchen started bubbling up and splitting at the seems. The flooring guy originally came and said that he believed it was sun damage coming from our glass sliding door. We ended up replacing the door with uv protection glass and the flooring guy replaced the whole kitchen floor with a moisture barrier paper underneath. During the demo they said there was possible moisture on the floor. We had a plumber out and he determined we did not have a leak. Just a few months later it started to happen again in a different area of the kitchen. When they installed the lvp originally they went right over tile, so this time he took up the tile as well so we could see what was happening. There was no obvious water or leak. We then had all our pipes looked at. Our drain pipes scooped. Inside and outside, pool, etc. Spent a ton of $ on tests. There was no leak to be found. We think we must have a foundation slab that has a high moisture content or the soil below has a lot of moisture? That’s all we could come up with.

This time for the 3rd installation they put down a moisture barrier epoxy, a wood plank sub floor, and glued the lvp down to that. It made it a year after that, but we have the same problem happening again. So they have replaced the flooring in the kitchen 3 times in less than 3 years and it needs to be replaced again now. We had the manufacturer out and they of course blamed the installation. It is mind boggling. We have had so many plumbers, and flooring companies out and no one has ever agreed on what the problem is.

So, I have to replace the kitchen floors again and this time need to do something other than the LVP that matches the rest of the house. I have heard about epoxy/ painted concrete flooring and thought that might flow better than tile. Do you have a knowledge as to if it would hold up to moisture fumes as that is our best guess as to the moisture problem we have?

Tile is the other option and that is what was originally in the house and there didn’t seem to be any issues with tile. any ideas?

averykc13Original Author