Big thanks to this site Sears reartine tiller

zach1101

16 years ago

Related Stories

LANDSCAPE DESIGNTo Manage Stormwater Sustainably, Understand Your Site

Follow this guide to learn how water moves through your landscape and how best to manage it

Full Story

MOST POPULAR8 Little Remodeling Touches That Make a Big Difference

Make your life easier while making your home nicer, with these design details you'll really appreciate

Full Story

HOUZZ TOURSHouzz Tour: Connecting to the Landscape in Melbourne

Views of iconic moonah trees and plenty of wood indoors help an Australian home connect with its site

Full Story

GARAGESTale of 2 Car Shelters: Craftsman Garage and Contemporary Carport

Projects in the Pacific Northwest complement the existing architecture and sites of 2 very different homes

Full Story

ARCHITECTURE10 Advantages of the Humble Ranch House

Boomer-friendly and not so big, the common ranch adapts to modern tastes for open plans, outdoor living and midcentury mojo

Full Story

DECORATING GUIDESSix Tips for Choosing the Perfect Sofa

Here's How to Get the Big, Comfy Couch You Really Want

Full Story

ECLECTIC HOMESMy Houzz: A Deconstructed Saltbox in the Hamptons

Modern sensibility meets farmhouse style, with a Chinese piece here and there, in a home near a New York nature sanctuary

Full Story

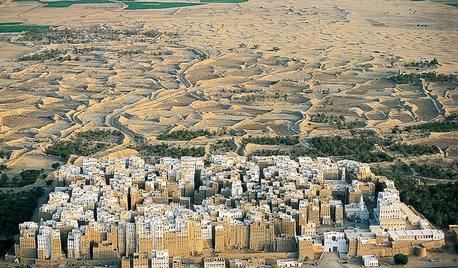

EVENTSOn Show: The Ingenuity of Ancient Architecture

A German exhibit celebrates the diversity of traditional homes built with materials at hand

Full Story

MOST POPULAREasy Green: 23 Ways to Reduce Waste at Home

Pick from this plethora of earth-friendly ideas to send less to the landfill and keep more money in your pocket

Full Story

KITCHEN DESIGNSteel Yourself: Industrial Kitchen Islands Are On a Roll

Sleek mobile islands can make traditional built-ins seem downright outmoded. Find the right idea for your kitchen

Full StoryMore Discussions

vandtbear1

rustyj14

Related Professionals

North New Hyde Park Landscape Architects & Landscape Designers · Saint Matthews Landscape Architects & Landscape Designers · Bethel Park Landscape Contractors · Brookfield Landscape Contractors · Hurricane Landscape Contractors · Lewisville Landscape Contractors · Muttontown Landscape Contractors · Pleasanton Landscape Contractors · Sugar Hill Landscape Contractors · Tehachapi Landscape Contractors · Uxbridge Landscape Contractors · Waipahu Landscape Contractors · Albemarle Decks, Patios & Outdoor Enclosures · Crestline Decks, Patios & Outdoor Enclosures · Larkspur Decks, Patios & Outdoor Enclosuresbrian8156

vandtbear1

brian8156

jabberinmonkey

Myeager2_aol_com

Plowdeep

earthworm

DadDude

Plowdeep

cbaggett

craig-ref