PVC drainage under concrete

bettydiy

14 years ago

Related Stories

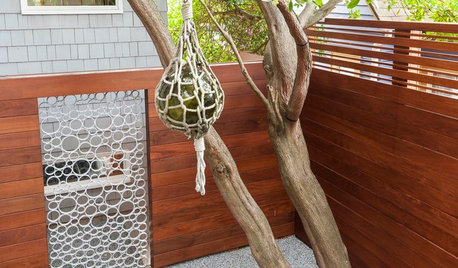

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

BATHROOM DESIGNConvert Your Tub Space Into a Shower — Waterproofing and Drainage

Step 4 in swapping your tub for a sleek new shower: Pick your waterproofing materials and drain, and don't forget to test

Full Story

HOUZZ TOURSHouzz Tour: Innovative Home Reunites Generations Under One Roof

Parents build a bright and sunny modern house where they can age in place alongside their 3 grown children and significant others

Full Story

MATERIALSPrecast Concrete Pavers Make a Versatile Surface in the Garden

You can use concrete pavers in a variety of shapes and colors for your patio, walkway, driveway and more

Full Story

CONCRETEWhy Concrete Wants to Crack

We look at the reasons concrete has a tendency to crack — and what you can do to help control it

Full Story

REMODELING GUIDESConcrete Driveways: Poring Over the Pros and Cons

Concrete adds smooth polish to driveways and a sleek look to home exteriors, but here are the points to ponder before you re-surface

Full Story

PATIOSLandscape Paving 101: Cast-in-Place Concrete

A construction standard, cast-in-place concrete can be used for a wide variety of project types

Full Story

GREAT HOME PROJECTSHow to Tear Down That Concrete Patio

Clear the path for plantings or a more modern patio design by demolishing all or part of the concrete in your yard

Full Story

FLOORSKnow Your Flooring: Concrete

Concrete floors have a raw and elegant beauty that can be surprisingly warm

Full Story

LANDSCAPE DESIGNOutdoor Style: Creative Ways With Classic Concrete

Have you cast concrete aside as being too dull or crack-prone? Learn about new design options along with the basics of using it outside

Full Story

dave777_2009

fixizin

Related Professionals

Hillcrest Heights Handyman · Bay Shore Kitchen & Bathroom Remodelers · Citrus Park Kitchen & Bathroom Remodelers · 20781 Kitchen & Bathroom Remodelers · Broadlands Kitchen & Bathroom Remodelers · Elk Grove Village Kitchen & Bathroom Remodelers · Hoffman Estates Kitchen & Bathroom Remodelers · Idaho Falls Kitchen & Bathroom Remodelers · Lakeside Kitchen & Bathroom Remodelers · Morgan Hill Kitchen & Bathroom Remodelers · South Park Township Kitchen & Bathroom Remodelers · Thonotosassa Kitchen & Bathroom Remodelers · Toms River Kitchen & Bathroom Remodelers · South Jordan Kitchen & Bathroom Remodelers · Ojus Kitchen & Bath Fixturesbrickeyee

lazypup

fixizin

lazypup