Build our own Wood Garage Door?

kendog2

8 years ago

Featured Answer

Sort by:Oldest

Comments (6)

randy427

8 years agotoxcrusadr

8 years agoRelated Professionals

Aspen Hill Interior Designers & Decorators · Garden Acres Interior Designers & Decorators · Linton Hall Interior Designers & Decorators · Ridgefield Park Interior Designers & Decorators · Westbury Interior Designers & Decorators · Langley Park Cabinets & Cabinetry · Alton Cabinets & Cabinetry · Daly City Cabinets & Cabinetry · Drexel Hill Cabinets & Cabinetry · Kaneohe Cabinets & Cabinetry · Kentwood Cabinets & Cabinetry · Key Biscayne Cabinets & Cabinetry · Prospect Heights Cabinets & Cabinetry · South Gate Cabinets & Cabinetry · North Bay Shore Cabinets & Cabinetrykendog2

8 years agorwiegand

8 years agotoxcrusadr

5 years ago

Related Stories

CONTEMPORARY HOMESHouzz Tour: Family Builds Its Dream Home on a Wooded Hillside

Light-filled spaces and modern furnishings suit an active family in a California foothill community

Full Story

LANDSCAPE DESIGNUnwind in Your Own Private Garden Escape

When the world is getting on your last nerve, an outdoor refuge can soothe and nurture. Here's how to design a garden with relaxing in mind

Full Story

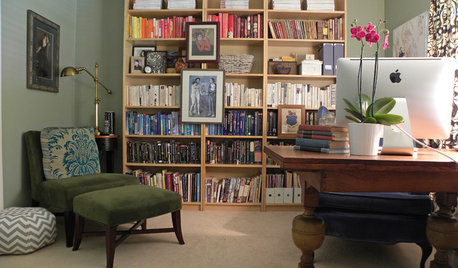

LIFESimple Pleasures: A Room of Your Own

Free up space for your own creative or meditative pursuits, and your dreams may have freer rein too

Full Story

DIY PROJECTSMake Your Own Barn-Style Door — in Any Size You Need

Low ceilings or odd-size doorways are no problem when you fashion a barn door from exterior siding and a closet track

Full Story

REMODELING GUIDESNesting Boxes: Houses With Homes of Their Own

Framing one box with another creates a whole new style of modern indoor-outdoor living

Full Story

BATHROOM DESIGN8 Tips for Creating Your Own Wet Room

Warm up a room full of tile with color, light, texture and wood

Full Story

GARDENING AND LANDSCAPINGHow to Get an Outdoor Kitchen of Your Own

New project for a new year: Build a cooking space for your yard or patio to make entertaining a breeze

Full Story

HOUSEKEEPINGChoose Your Own Spring Cleaning Plan

Instead of trying to do it all, pick one of these six cleaning approaches that’s right for you now

Full Story

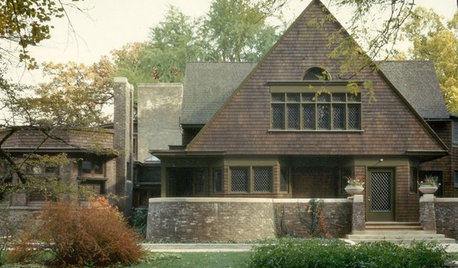

FRANK LLOYD WRIGHTWhat Frank Lloyd Wright's Own House Tells Us

The buildings dreamed up here changed the course of architecture — and Wright's home was no less a design lab than the studio itself

Full Story

HOUZZ TOURSHouzz Tour: A Modern Mountain Home Takes Off With Its Own Airstrip

In Colorado, a glass and concrete home hugs a former hayfield that’s now a launching pad for antique planes

Full Story

kendog2Original Author