Is 40 PSI XPS board a overkill for basement under slab insulation?

mqcola

2 years ago

Featured Answer

Sort by:Oldest

Comments (12)

mqcola

2 years agoRelated Professionals

Holliston Solar Energy Systems · Country Walk General Contractors · Centereach General Contractors · Enumclaw General Contractors · Leavenworth General Contractors · Leon Valley General Contractors · Murrysville General Contractors · Port Washington General Contractors · Springfield General Contractors · Palm River-Clair Mel General Contractors · De Pere Architects & Building Designers · American Fork Flooring Contractors · Chandler Flooring Contractors · Elmhurst Flooring Contractors · Little Falls Flooring Contractorsmqcola

2 years agomqcola

2 years agomqcola

2 years agomqcola

2 years ago

Related Stories

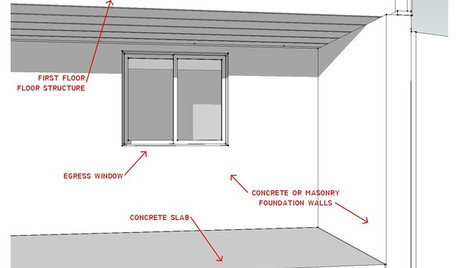

REMODELING GUIDESKnow Your House: The Steps in Finishing a Basement

Learn what it takes to finish a basement before you consider converting it into a playroom, office, guest room or gym

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

BASEMENTSDesign Workshop: Is It Time to Let Basements Become Extinct?

Costly and often unnecessary, basements may become obsolete — if they aren’t already. Here are responses to every reason to keep them around

Full Story

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

REMODELING GUIDES10 Tips for Renovating Your Basement

A professional contractor shares her tips on what to consider before you commit to a basement remodel

Full Story

KITCHEN DESIGN11 Must-Haves in a Designer’s Dream Kitchen

Custom cabinets, a slab backsplash, drawer dishwashers — what’s on your wish list?

Full Story

THE HARDWORKING HOMEWhere to Put the Laundry Room

The Hardworking Home: We weigh the pros and cons of washing your clothes in the basement, kitchen, bathroom and more

Full Story

FLOORSFloors Warm Up to Radiant Heat

Toasty toes and money saved are just two benefits of radiant heat under your concrete, wood or tile floors

Full Story

Houzz Call: What Gives You the Creeps at Home?

Halloween horror got nothing on your basement, attic or closet? Show us that scary spot you steer clear of

Full Story

HU-867564120