Greenhouse wall and foundation insulation

wildlifegardenermt

15 years ago

Related Stories

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

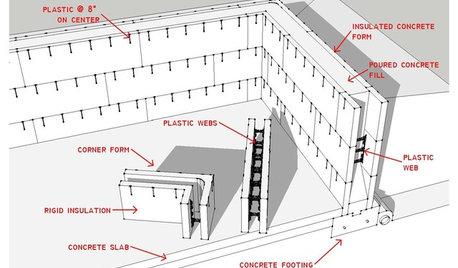

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

GREEN BUILDINGInsulation Basics: Designing for Temperature Extremes in Any Season

Stay comfy during unpredictable weather — and prevent unexpected bills — by efficiently insulating and shading your home

Full Story

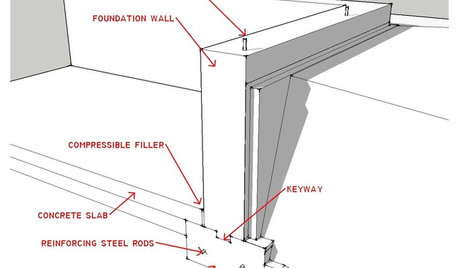

ARCHITECTUREKnow Your House: What Makes Up a Home's Foundation

Learn the components of a common foundation and their purpose to ensure a strong and stable house for years to come

Full Story

GARDENING AND LANDSCAPINGSee a Family Greenhouse Grown From Scraps

Can-do resourcefulness and less than $400 lead to a new 8- by 8-foot home for plants on a Tennessee family's property

Full Story

OUTBUILDINGSStudio Solution: A Kit Greenhouse Becomes a Creative Private Office

See how an inventive work-from-home designer made an office from a greenhouse, for some inspired thinking in the backyard

Full Story

GREENHOUSESA Greenhouse Rises From Texas Tornado Wreckage

Barn damage became a blessing in disguise for a thrifty, creative couple with a hankering for more greenery

Full Story

LANDSCAPE DESIGNA Luxury Greenhouse Lures Manhattanites to the Country

Industrial meets rustic in this stunning new structure for living and entertaining in rural Pennsylvania

Full Story

OUTBUILDINGSRoom of the Day: An Old Shed Becomes a Spa and Greenhouse

A garden-loving couple create the perfect place to have a soak and putter with their plants year-round

Full Story

stressbaby

wildlifegardenermtOriginal Author

Related Professionals

Belmont Landscape Architects & Landscape Designers · Horsham Landscape Architects & Landscape Designers · Hyattsville Landscape Architects & Landscape Designers · Dallas Landscape Contractors · Deerfield Landscape Contractors · East Patchogue Landscape Contractors · Federal Way Landscape Contractors · Gurnee Landscape Contractors · Lebanon Landscape Contractors · Metairie Landscape Contractors · San Bruno Landscape Contractors · Markham Landscape Contractors · Forest Park Solar Energy Systems · Imperial Beach Solar Energy Systems · Weymouth Solar Energy Systemstsmith2579

stressbaby

lilydude

birdwidow

wildlifegardenermtOriginal Author

stressbaby

boxcar_grower

birdwidow

jbest123

mizwilly