Form or no form?

jlwelter83

10 years ago

Related Stories

VINTAGE STYLEVintage Style: Dress Up a Dress Form

Embellish a dress form for a fashion-minded accent that reflects your latest mood

Full Story

DESIGN DICTIONARYBoard-Formed Concrete

Pouring concrete the old-school way leaves attractive wood-grain textural imprints

Full Story

DECORATING GUIDESMosaics Bring a Classical Art Form Home

Tile Art Adds Personal Style to a Backsplash, Bathroom, Fireplace or Patio

Full Story

REMODELING GUIDESModern Design Meets Traditional Forms

Contemporary Vernacular: Melding Today's Comforts With Indigenous Design

Full Story

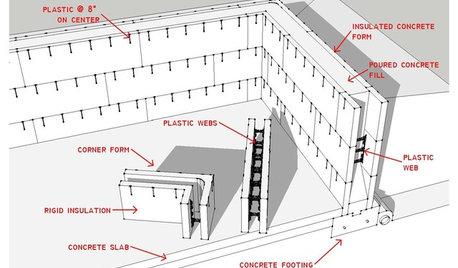

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

ARCHITECTURERounded Forms Smooth Modern Architecture’s Edges

A simple curve or fluid line can soften and add interest to the look of your house, inside and out

Full Story

TRADITIONAL ARCHITECTURERoots of Style: Colonial Revivals Span Eras and Forms

Are the varied influences and configurations to thank for colonial revivals' ongoing popularity? Judge for yourself

Full Story

DECORATING STYLESOrganic Forms: Nature's Symbols in Home Décor

The shapes of forest, flower and meadow add to enchanting interior designs

Full Story

TREES11 Japanese Maples for Breathtaking Color and Form

With such a wide range to choose from, there’s a beautiful Japanese maple to suit almost any setting

Full Story

VC Studio Inc.

jlwelter83Original Author

VC Studio Inc.

HEGER ARCHITECTS

VC Studio Inc.