The Basics: seams, pressing, etc.

K8Orlando

13 years ago

Related Stories

DECORATING GUIDESHot Off the Press: Design Sponge At Home

Grace Bonney's blog-gone-book is as practical as it is inspirational

Full Story0

MATERIALSRaw Materials Revealed: Drywall Basics

Learn about the different sizes and types of this construction material for walls, plus which kinds work best for which rooms

Full Story

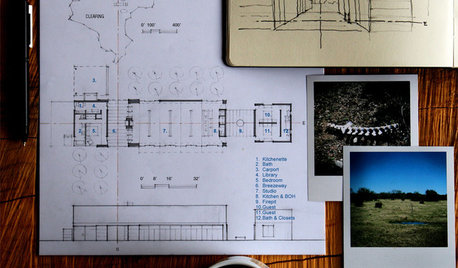

ARCHITECTUREDesign Practice: The Basics of Marketing Your Business

Pro to pro: Attract clients and get paying work by drawing attention to your brand in the right places

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

KITCHEN ISLANDSWhat to Consider With an Extra-Long Kitchen Island

More prep, seating and storage space? Check. But you’ll need to factor in traffic flow, seams and more when designing a long island

Full Story

CONTRACTOR TIPSWhat to Look for in a Contractor's Contract

10 basic ingredients for a contract will help pave the way to remodel happiness

Full Story

GREEN BUILDINGLet’s Clear Up Some Confusion About Solar Panels

Different panel types do different things. If you want solar energy for your home, get the basics here first

Full Story

DECORATING GUIDESHow to Get Your Furniture Arrangement Right

Follow these 10 basic layout rules for a polished, pulled-together look in any room

Full Story

GREEN BUILDINGWhy You Might Want to Build a House of Straw

Straw bales are cheap, easy to find and DIY-friendly. Get the basics on building with this renewable, ecofriendly material

Full Story

LIFE10 Smart Organizing Ideas That Make Life Easier

Rethink where and how you store household basics, from bills to baking supplies, to buy some time and save some headaches

Full StorySponsored

Your Custom Bath Designers & Remodelers in Columbus I 10X Best Houzz

More Discussions

geezerfolks_SharonG_FL

User

Related Professionals

Austin Furniture & Accessories · Midland Furniture & Accessories · Savannah Furniture & Accessories · Aliso Viejo Furniture & Accessories · Culver City Furniture & Accessories · Port Chester Furniture & Accessories · Carpinteria Furniture & Accessories · Ashwaubenon Interior Designers & Decorators · Ogden Interior Designers & Decorators · Damascus Flooring Contractors · Oshkosh Flooring Contractors · Sun City Flooring Contractors · Uxbridge Flooring Contractors · West Chester Flooring Contractors · San Elizario Furniture & Accessoriesteresa_nc7

nanajayne

barbara_l

teresa_nc7

wendyfaye

cindykg23

day2day

chickie1

K8OrlandoOriginal Author

sandlapper_rose

wendyfaye

magothyrivergirl

toolgranny

magothyrivergirl

nanajayne

rosajoe_gw

buteau3rd

murphy_zone7

User

wendyfaye