motion sensor to actuate fan, relay needed?

gratefulgary

13 years ago

Related Stories

MOVING10 Rooms That Show You Don’t Need to Move to Get More Space

Daydreaming about moving or expanding but not sure if it’s practical right now? Consider these alternatives

Full Story

BATHROOM DESIGN6 Elements of a Perfect Bathroom Paint Job

High-quality paint alone won't cut it. For the best-looking painted bathroom walls, you'll need to get these other details right

Full Story

BATHROOM DESIGN9 Big Space-Saving Ideas for Tiny Bathrooms

Look to these layouts and features to fit everything you need in the bath without feeling crammed in

Full Story

GARAGESKey Measurements for the Perfect Garage

Get the dimensions that will let you fit one or more cars in your garage, plus storage and other needs

Full Story

KITCHEN SINKSJust a Touch: Faucets Without the Fuss

Faucets that turn on with a tap of the finger, forearm or hand are great for messy hands or full arms

Full Story

GREEN BUILDINGMy Houzz: Sustainability Meets Global Style on an Australian Hilltop

It puts the power of the sun to work while keeping the budget in check and family socializing front and center

Full Story

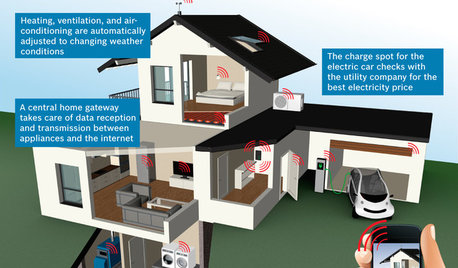

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

LIGHTINGWhat to Know About Switching to LED Lightbulbs

If you’ve been thinking about changing over to LEDs but aren't sure how to do it and which to buy, this story is for you

Full Story

HOME TECHOn the Internet, Nobody Knows You're a Lamp

Home appliances and devices are poised to get on the Internet and start messaging one another. Here's why that'll be great for you

Full Story

BATHROOM DESIGNWindows That Expose Your Bathroom to Light Without Exposing You

Enjoy the best of both worlds with window tricks that give you privacy along with the views and natural light

Full Story

brickeyee

pharkus

Related Professionals

Endicott General Contractors · Nampa General Contractors · Roseburg General Contractors · Phoenix Solar Energy Systems · East Lake Solar Energy Systems · Maple Grove Solar Energy Systems · Rehoboth Solar Energy Systems · Waltham Solar Energy Systems · Wasco Solar Energy Systems · Brookfield Home Automation & Home Media · La Crescenta-Montrose Home Automation & Home Media · Lewisville Home Automation & Home Media · Springville Home Automation & Home Media · Winchester Home Automation & Home Media · Weston Home Automation & Home Mediabrickeyee

gratefulgaryOriginal Author

pharkus

yosemitebill

gratefulgaryOriginal Author

brickeyee

pharkus

windslam

pharkus

brickeyee

windslam

jmorrow

pharkus

alan_s_thefirst

pharkus

alan_s_thefirst